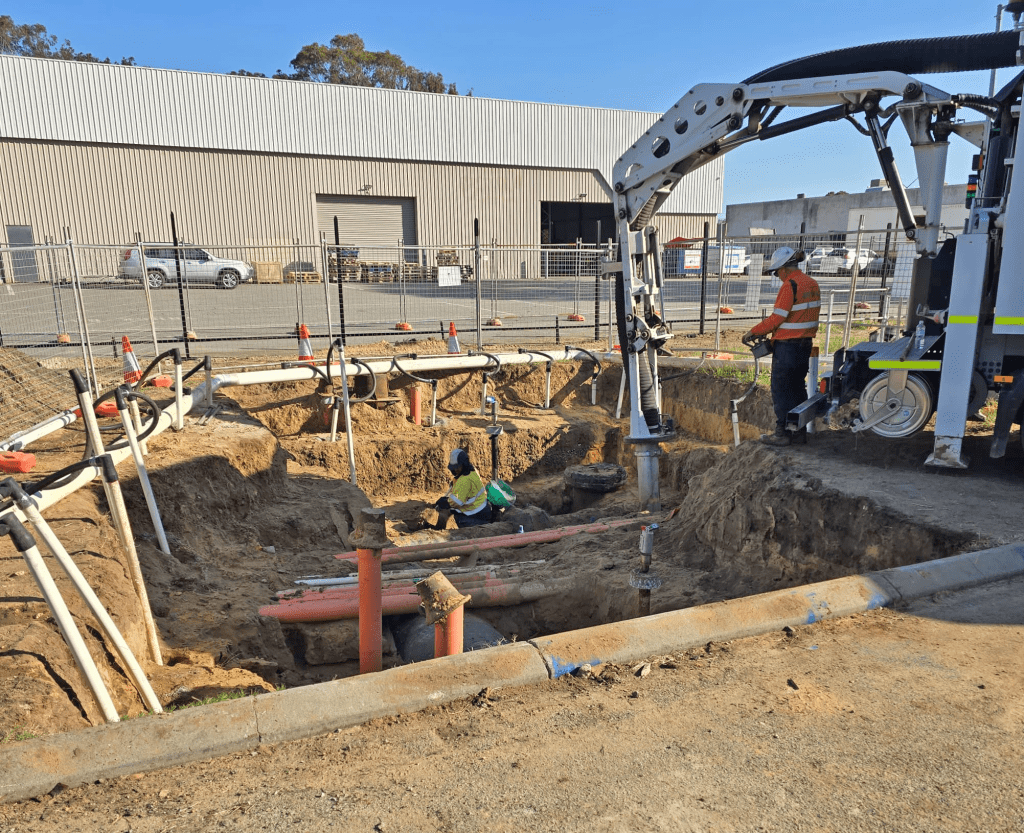

Critical valve replacements on DN1000 and DN600 pipelines at Belmont Pump Station required precise excavation within a heavily congested utilities corridor containing high-pressure water, communications, power, and existing water assets. With a scheduled shutdown in place, the environment posed a high risk where any contact with live services could result in major disruption, safety hazards, and significant delays. A controlled, non-destructive excavation methodology was essential to maintain safety and keep the shutdown program on track.

Client: Water Corporation

Working in close proximity to live services, DryVac technology unit enabled safe and efficient excavation around both valves, achieving:

- Up to 40m³ per day

- Excavation depths of up to 3.5 metres

- Production rates averaging 8m³ per hour

- Full control around critical live assets.

Groundwater was controlled through a temporary dewatering system, stabilising the trench and ensuring uninterrupted DryVac productivity throughout the works.

Three-Step Strategic Approach

Service Exposure and Identification

DryVac excavation was deployed to expose and positively identify surrounding live services, allowing the replacement works to proceed with confidence in a highly congested environment.

Non-Destructive Excavation and Access Creation

Approximately 80m3 of material was excavated using DryVac technology, providing safe access around and beneath the pipe for cutting and welding, while maintaining clearance from critical live services.

On-Time Delivery Within Shutdown Window

Both excavations were completed within a two-day period, ensuring valve replacement works proceeded without delay and the Water Corporation shutdown timeline was met.

MacroVac’s rapid mobilisation, precise non-destructive excavation methodology, and productivity in complex, high-risk environments helped ensure the works were completed safely within the shutdown period. This project demonstrates MacroVac’s capability to support critical shutdown activities where timing, safety, and performance are paramount.