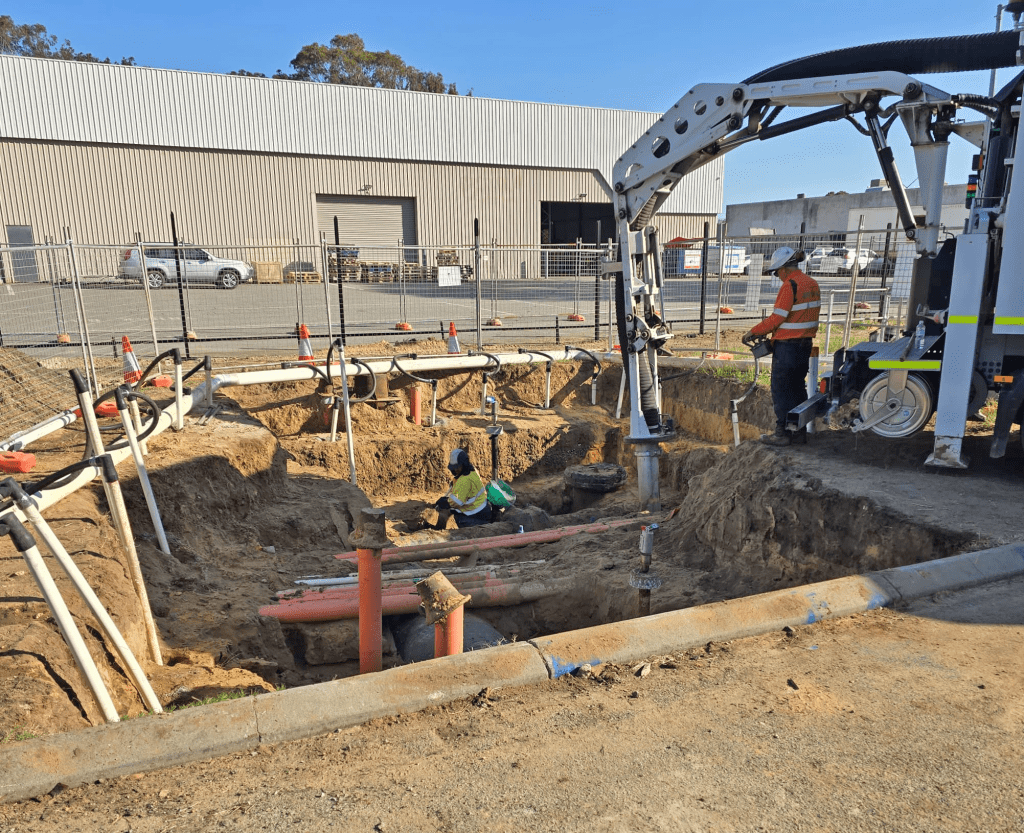

Protecting Critical Assets in a Live Utility Zone.

METRONET alliance contractors required a non-mechanical excavation solution to protect live underground assets, including fuel, gas, and cable mains. MACROVAC’s dry vac system safely removed material without damaging infrastructure. The process eliminated ‘line of fire’ risks, reused excavated material for backfill, and ensured uninterrupted rail freight operations.

Clients: NWA and ALUA

The Challenge

METRONET alliance contractors required a safe, effective, productive excavation system that would not damage critical live underground assets which included:

• BP KWOL Fuel main which provides aviation fuel to Perth Airport. (NWA)

• ATCO High Pressure Gas Mains (NWA & ALUA)

• MCR ( Mains Cable Route) – (NWA & ALUA)

All critical underground assets were “live” and a mechanical excavation exclusion zone was in place, thereby eliminating conventional open trenching as potential incidents impact associated were deemed to be extremely high risk relative to safety, environmental, operations and community impacts.

The Solution

MACROVAC dry vac unit completed the removal of the material around and underneath the fuel pipe using a combination of steel and HDPE suction tube, the HDPE tube was utilised immediately around the mains so that the risk of damage to the pipe coatings was eliminated. MACROVAC used onboard ancillary equipment (Air lance, Air Spade) to break down clay material in conjunction with the suction tube clearing material as it was fractured out.

The Outcome

• The Dry vac provided the safest solution to excavate material.

• Being a dry vacuum process, the material removed was re-used in the backfilling process.

• Successful use of the HDPE suction tube to eliminate pipe coating damage to both the HP Gas and BP KWOL fuel line.

• Elimination of any potential “line of fire” risks for workers.

• Eliminated risk of rail freight stoppages because of any potential damage to MCR cable.

Conclusion

The use of MACROVAC on this project ensured a safe and efficient excavation process around live services. The HDPE suction tube prevented damage to fuel and gas main coatings, while high production efficiency minimised the time required for fuel, gas, and cable spotter activities. Additionally, operations were completed without interrupting rail freight, ensuring seamless project execution.