Minimising Risk in a High-Stakes Environment.

West Coast Civil used MACROVAC at Perth Airport to safely excavate around a live fuel main without damaging its protective coating. The dry vacuum process enabled precise material removal, reused in-situ backfill, and eliminated waste. Efficient suction technology ensured a safe, cost-effective solution with no disruption to airport operations.

Client: West Coast Civil

The Challenge

WCC required a system that would vacuum excavate around existing live Fuel main which provides aviation fuel to Perth Airport. The existing main was required to be installed to a deeper level to comply with cover requirements. The steel fuel main had a protective coating which could not be damaged as this would impact the cathodic protection requirements for the live main. The main had to remain active for fuel supply to the airport. Conventional open trenching was not a consideration as potential incident risks associated were deemed to be extremely high from a safety, environmental and operational aspect.

The Solution

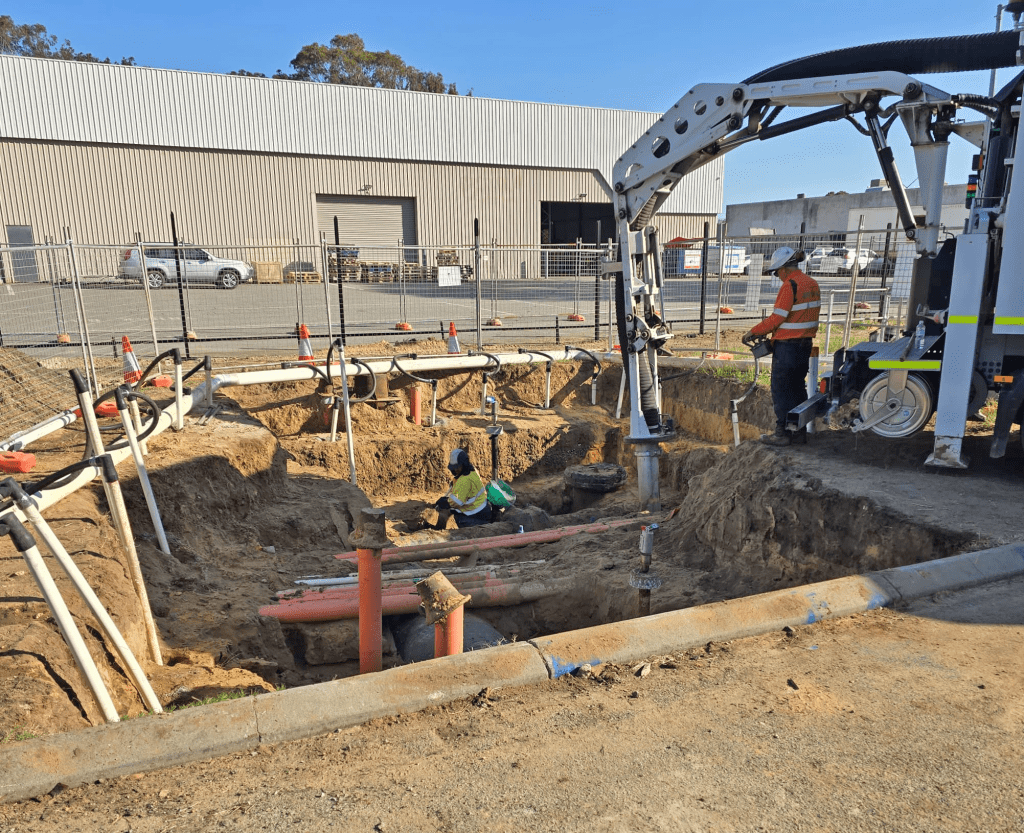

MACROVAC dry vac unit completed the removal of the material around and underneath the fuel pipe using a combination of steel and HDPE suction tube, the HDPE tube was utilized immediately around the main so that the risk of damage to the pipe coating was eliminated. Sections of the fuel line had been installed within a coffee rock layer, MACROVAC used onboard ancillary equipment (Air lance, Air Spade) to break down this material in conjunction with the suction tube clearing material as it was fractured out.

The Outcome

• The Dry vac provided the safest solution to excavate material.

• The existing main was lowered to the new level without incident.

• Being a dry vacuum process, the material removed was re-used in the backfilling process.

• Successful Use of the HDPE suction tube to eliminate pipe coating damage.

• Elimination of any potential “line of fire” risks for workers.

Conclusion

The use of MACROVAC on this project delivered a cost-effective and environmentally friendly solution. The dry vacuum process allowed in-situ material to be reused for backfilling, eliminating the need for imported fill and avoiding sludge or slurry waste disposal costs. The 10” intake suction tube and 8m³ side tipper bin maximised productivity, while the sealed storage bin prevented dust dispersion, ensuring airport operations, including flights, remained unaffected.