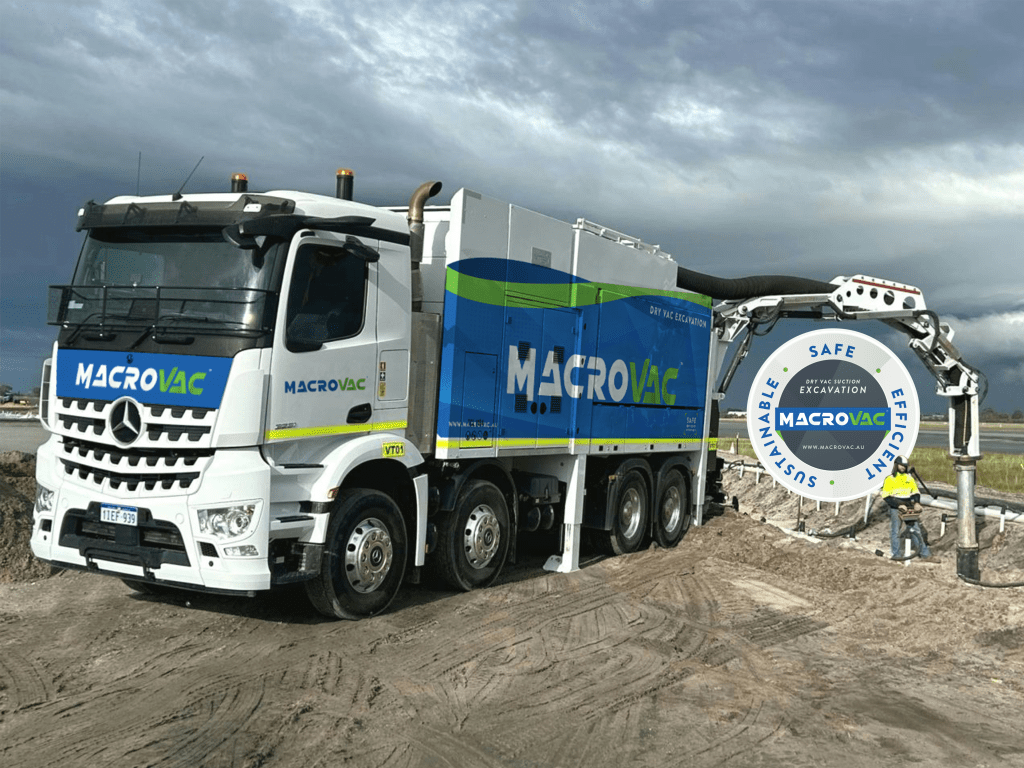

Safe, Efficient and Sustainable

Dry vac excavation is the smarter, cleaner, and more sustainable choice for your next project. Whether you’re working on utilities, construction, or environmental projects, our advanced dry vacuum technology guarantees precision, safety, and cost-efficiency.

+

Safe: Reduces risks to workers and nearby utilities.

+

Efficient: No need for slurry disposal, saving time and costs.

+

Sustainable: Reuse excavated material on-site, minimising waste and environmental impact.

Safe

MACROVAC dry vacuum excavation offers a non-destructive excavation alternative, minimising risks to workers and nearby utilities and enhancing on-site safety and precision. Our solution significantly reduces the hazards associated with traditional excavation techniques.

Efficient

By eliminating the need for slurry disposal, our dry vac technology streamlines the excavation process, saving time on unnecessary trips and reducing overall costs, ensuring projects stay on schedule and within budget while maximising productivity.

Sustainable

The ability to reuse excavated materials directly on-site reduces waste, eliminates the need for additional transport or landfill use, and supports environmentally conscious construction practices for a greener future.

case studies

PROVEN SUCCESS IN EVERY PROJECT

At MACROVAC, we pride ourselves on delivering outstanding results for a variety of clients across Perth metropolitan and regional areas. Explore our case studies to see how our safe, efficient, and sustainable methods have made a difference.

-

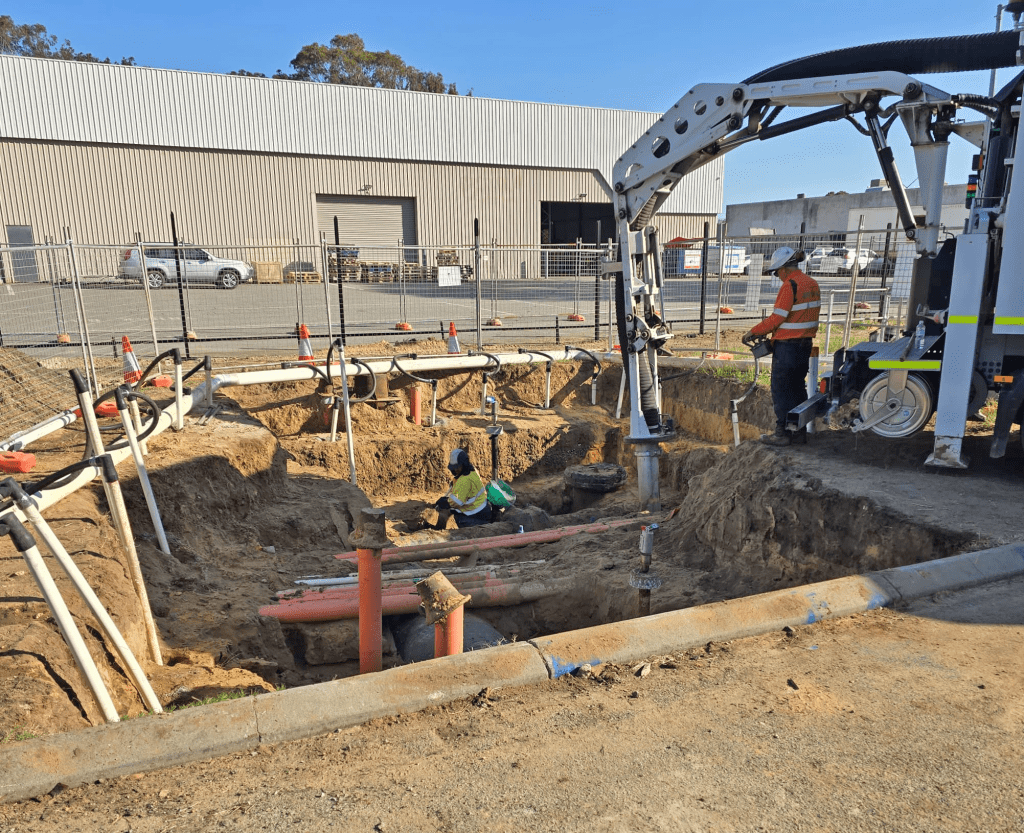

Critical Valve Replacement – Belmont PS Rosegardens, WA

Critical valve replacements on DN1000 and DN600 pipelines at Belmont Pump Station required precise excavation within a heavily congested utilities corridor containing high-pressure water, communications, power, and existing water assets. With a scheduled shutdown in place, the environment posed a high risk where any contact with live services could result in major disruption, safety hazards,

-

Precision Excavation for METRONET’s Live Assets.

Protecting Critical Assets in a Live Utility Zone. METRONET alliance contractors required a non-mechanical excavation solution to protect live underground assets, including fuel, gas, and cable mains. MACROVAC’s dry vac system safely removed material without damaging infrastructure. The process eliminated ‘line of fire’ risks, reused excavated material for backfill, and ensured uninterrupted rail freight operations.

-

Perth Airport – Safe & Efficient Excavation with MACROVAC.

Minimising Risk in a High-Stakes Environment. West Coast Civil used MACROVAC at Perth Airport to safely excavate around a live fuel main without damaging its protective coating. The dry vacuum process enabled precise material removal, reused in-situ backfill, and eliminated waste. Efficient suction technology ensured a safe, cost-effective solution with no disruption to airport operations.

“

The dry vac excavation truck has provided our clients the assurance that our non-destructive excavation technique is the safest way to locate services and conduct trench excavation.”

Barry Crowley

General Manager & Director